Food-Grade Air Compressor Oil: What It Is, When You Need It, How to Choose

Posted by IAP on 09/30/2025

Compressed air touches cans, bags, and pills more often than most teams realize. If the wrong oil is in the system, you’re risking contamination, QA holds, and expensive downtime. For food, beverage, and pharmaceutical packaging lines, “regular” compressor oil isn’t an option.

This guide explains when food-grade oil is required, how it differs from standard lubricants, how to select the right product for your compressor, and how to change over cleanly. When you’re ready, shop IAP’s approved food-grade oils and streamline purchasing across all your lines.

Quick Links

- Shop Food-Grade Oils

- Shop All Compressor Oils

- Free IAP Oil Analysis

- Air Treatment

- Contact IAP here or call (414) 422-1717 for product selection help

Food-Grade Air Compressor Oil vs. Regular Oil - What Makes It Different

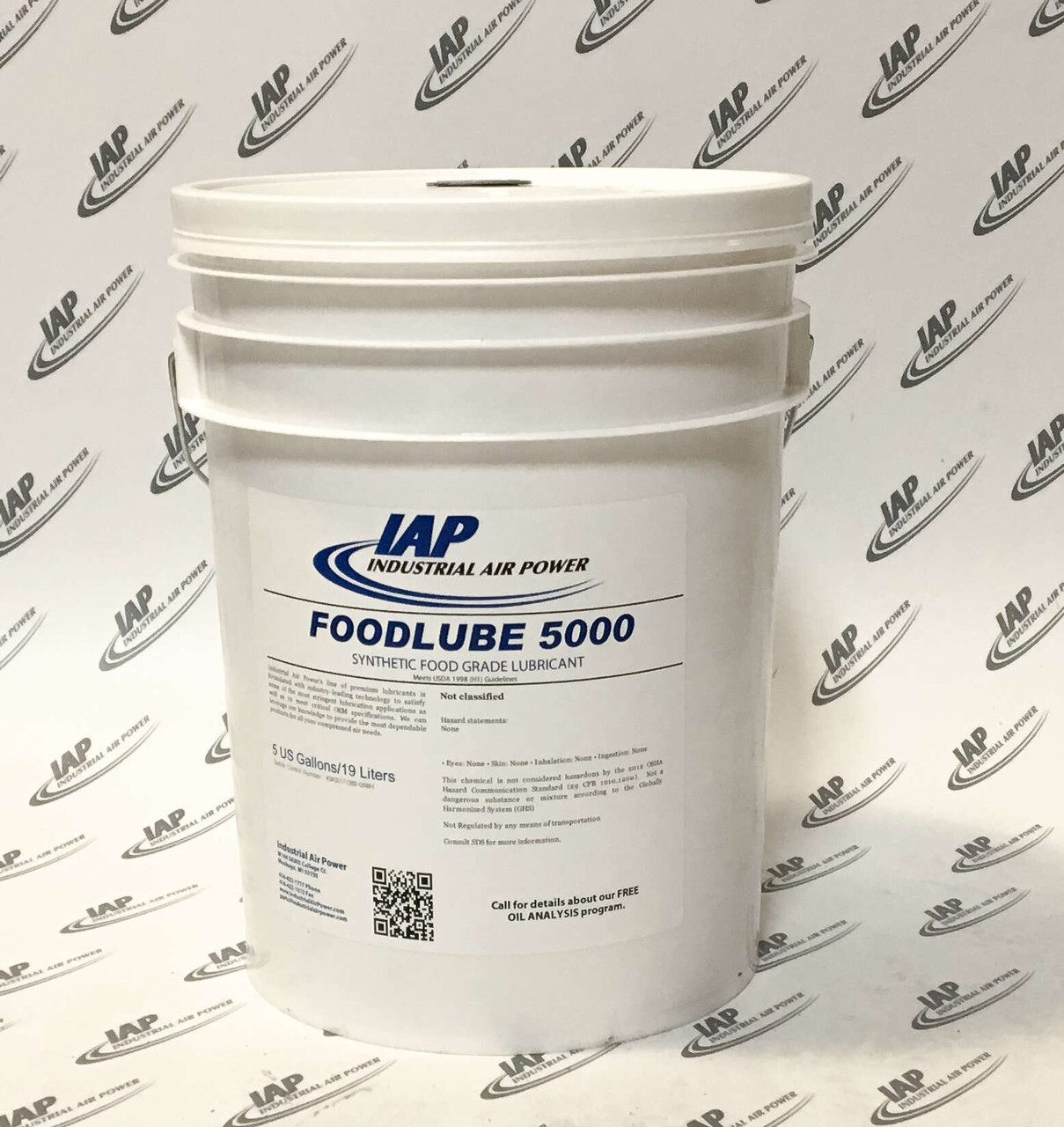

Food-grade compressor oils are engineered and approved for environments where compressed air may have incidental contact with product, primary packaging, or clean surfaces. They’re formulated to deliver the equipment protection your compressor needs while meeting compliance expectations in regulated plants.

What Sets Them Apart:

- Approval/Compliance: IAP’s food-grade air compressor oils are USDA & kosher approved to support regulated environments.

- Dual Mandate: They defend against wear, rust, and corrosion while also supporting hygiene and cleanliness goals.

- No Shortcuts: In sensitive areas, “close enough” is not acceptable. Inventory, labeling, and changeover discipline matter.

Where Food-Grade Oils Are Required (Use-Case Checklist)

If any of the following are true, you should be using food-grade lubricants in the relevant compressor(s) and air networks:

- Canned Beverages: soda, beer, seltzer, juice. Think air knives, blow-offs, conveyors, and actuators on fill/seam lines.

- Bagged Foods: Form-fill-seal equipment, on-line pickers, and general packaging pneumatics. Think chips, frozen vegetables, or bread.

- Pharmaceuticals: tablet/capsule production and packaging, blister and bottling lines.

- Any process where compressed air may contact product or the interior of primary packaging, or is used to purge/clean food-contact surfaces.

If there’s any doubt, standardize up. It's simpler to keep sensitive areas on food-grade than to manage risky exceptions.

How Food-Grade Oils Protect Equipment and Your Product

Food-grade doesn’t mean “light duty.” The right oil still has to protect compressors running long hours in humid, washdown-heavy plants.

- Wear Protection: Reduces friction on bearings, rotors, and rings.

- Rust and Corrosion Resistance: Important in facilities with frequent washdowns or variable humidity.

- Clean Operation: Helps control deposits that lead to valve sticking or elevated discharge temps.

- Compatibility: IAP’s lubricants are engineered to be 100% compatible with the OEM lubricants they replace, and tested with seals, O-rings, gaskets, and hoses.

Choosing the Right Food-Grade Oil - Step-by-Step

1. Start with the compressor and OEM specs

Rotary screw vs. reciprocating, operating temp range, and OEM recommendations determine base oil type and viscosity. Follow the spec sheet; don’t guess. If you don’t have the manual handy, IAP’s Parts Books & Manuals can help you find the right callout or part number equivalents when selecting OEM-labeled options.

2. Match the Viscosity/Grade

Use the OEM-recommended grade for your ambient and duty cycle. Avoid mixing grades; it complicates analysis and interval planning.

3. Choose the base oil that fits your goals

- Petroleum: Solid performance with lower upfront cost; typically shorter drains

- Semi-Synthetic: Balance of cost and performance; improved oxidation stability

- Full Synthetic: High thermal stability and cleanliness; often preferred in hot or continuous-duty lines to stabilize drains (validate with oil analysis)

4. Consider Your Drain Strategy

OEM intervals are a baseline. Your actual interval depends on discharge temperature, load/unload profile, ambient conditions, and contamination risk. Use IAP’s Free Oil Analysis to set intervals based on data rather than guesswork.

5. Seal & Elastomer Compatibility

Food-grade oils from IAP are tested for compatibility with common compressor materials. If you’ve had historical seal issues, note the material type and confirm before purchase.

6. OEM-Branded vs. Direct OEM Equivalents

- OEM Label Preference: Choose food-grade oils from your compressor brand. Atlas Copco, Gardner Denver, Ingersoll Rand, Quincy, and more are stocked by IAP.

- Cost Control: IAP’s compatible food-grade lubricants deliver the spec performance and compliance you need with strong value.

- Availability: Many lubricants are in stock, ready to ship. Filter by gallon size or brand, or search by part number/model.

Need a sanity check before ordering?

→ Contact IAP here or call (414) 422-1717 for product selection help

Don’t Forget Air Quality: Pair Oil Choice with Proper Air Treatment

Even with the correct oil, air quality depends on your dryer and filtration train. In food/beverage/pharma, the typical stack includes:

- Dryer sized to your flow/temperature (refrigerated or desiccant based on dew point targets)

- Coalescing filters (pre- and post-dryer as required) to reduce oil aerosol/carryover

- Point-of-use filters on packaging and filling lines where incidental contact risk is highest

- DP guages and planned element changes to avoid saturated filters and pressure drop penalties

If your QA team is chasing residues or odors, tighten the air treatment first, then re-evaluate drains and oil type.

Changing Over to Food-Grade Oil (Clean, Compliant Start)

A clean changeover keeps you compliant and makes your oil analysis meaningful. High-level best practices:

- Plan downtime and stage materials (oil, filters, separators)

- LOTO and fully depressurize the system

- Drain oil thoroughly; capture and dispose per your facility’s environmental procedures

- Replace filters/separators as required by the OEM to prevent carryover from old oil

- Refill with approved food-grade oil at the correct volume

- Label clearly (reservoir, sight glass area, and maintenance logs) so no one tops off with non-food-grade

- Monitor on restart: look for stable temperature/amp draw and normal sound profile

- Pull a baseline oil sample after the first short run-in to anchor future trend analysis

Questions about changeover materials?

Verify Performance with Free Oil Analysis - Maximize Uptime

IAP’s Oil Analysis Program is FREE and run by an independent lab. Each report includes viscosity, TAN (Total Acid Number), additive profile, wear metals, and water content, the fastest way to catch oxidation, coolant leaks, or early bearing wear before it becomes downtime.

How it works:

- Request your kit

- Pull

- Ship

Why Buy Food-Grade Oils from IAP - Proof Points That Matter

- Industry Approved: Complete line of USDA and Kosher approved food-grade oils

- Multi-brand depth: OEM food-grade oils for Atlas Copco, Gardner Denver, Ingersoll Rand, Quincy, and more, plus IAP’s own line of options

- Compatibility Guarantee: IAP lubricants are 100% compatible with their intended OEM lubricants and tested with seals, O-rings, gaskets, and hoses

- Inventory Ready: Many lubricants are in stock, ready to ship. Filter by gallon size or brand, or search by part number/model

- Scale & Savings: 300,000+ parts, lubricants, and accessories, often up to 40% less than local dealers

- Create an account for business pricing, early offer access, and faster checkout

Quick Selector: Which Food-Grade Oil Fits My Situation?

- Cost Control & Compliance: Use an IAP compatible food-grade equivalent that matches your OEM spec; confirm with oil analysis and label your reservoirs

- OEM Label Preference: Choose the OEM food-grade oil for your make/model (Atlas Copco, Gardner Denver, Ingersoll Rand, Quincy, and more)

- Harsh Duty/Long Drains: Consider synthetic food-grade to stabilize intervals at higher discharge temps (verify with oil analysis)

- Humidoty/Washdown: Prioritize oils with strong corrosion resistance and ensure coalescing filtration is fresh

FAQs - Straight Answers

Can I use regular compressor oil in food/beverage/pharma areas?

No. If compressed air may contact product, primary packaging interiors, or clean food-contact surfaces, use an approved food-grade oil.

Can I mix oils?

No. Mixing complicates analysis and can compromise performance. If you’re switching, plan a proper changeover and replace filters/separators as required.

How often should I change food-grade oil?

Start with OEM guidance and tune it using oil analysis for your actual temperature and duty cycle. That’s the fastest path to safe, cost-effective intervals.

Do I need new filters when switching?

Yes, new oil with saturated filters defeats the purpose. Replace or reset filtration/separation per OEM to begin with a clean baseline.

Next Steps - Buy, Verify, Standardize

- Standardize sensitive areas on approved food-grade oil, label systems, and train techs to avoid cross-fills

- Use Free Oil Analysis to dial in drain intervals

- Tighten air treatment where carryover or odors are noted

- Create IAP account to centralize purchasing for unmatched pricing, consistent availability, and fast shipping

Prefer to talk through it?

Contact IAP here or call (414) 422-1717 for product selection help

Need other compressor oil?

Streamline Your Complete Compressor System