AirEnd Rebuilding Procedure

Once we receive your airend, it is taken to the disassembly area, which contains a mounting stand, overhead crane and oil pit for collecting waste oil. The airend is then assigned a work order number, and a job folder is generated to hold all documents related to disassembly, teardown and dimensional specs. This folder stays with the airend through the entire rebuilding process to ensure accurate documentation from start to finish.

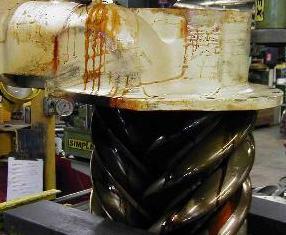

Once the airend is completely disassembled, the rotors, bearing carriers and end plates are checked for wear & all measurements are recorded. Pictures are taken identifying the problem areas. The disassembled airend is then placed in a self contained cleaning system to remove all grease, sludge and debris.

After the airend is completely cleaned & degreased, any parts that require machine work are brought to various areas of the shop and the repairs begin. If necessary, the following repairs will be made The front and rear covers can be metalized using a thermal ARC system. Finish machining is done on the appropriate Blanchard grinder. The rotors are be mounted and turned on a lathe. Bearing journals can be metalized and ground according to OEM specs.

Disassembled Airend

Polished End Plate

End Plate

Sealing Strip

The main bore areas can be metalized and bored on a vertical boring mill. Sealing strips can be built up and re-cut on our custom jig. Depending on the extent of the damage, the above work normally takes 1 to 2 days to complete.

Shaft Before Repair

Shaft After Repair

Complete Airend Rebuild

All components are then cleaned again and taken to the assembly area, where all bearings, seals, gaskets, and related materials needed to complete the assembly are pulled from inventory. Before assembly takes place all the dimensions are rechecked including the bearing pockets, bores and alignments. Both rotors are also checked for proper balance and alignment. The new bearings are measured for proper fit before installing. The airend is then completely re-assembled. After assembly the airend is spun unloaded for a final check.

To insure that the OEM specs are being met, the unit is continually measured and rechecked for accuracy during the entire rebuilding process. Upon completion, all open ports are plugged with plastic caps and the inlet is sealed shut.

The airend is now ready to be skid mounted and painted the original OEM color. As units enter the shipping area, all necessary shipping documents and startup procedures are attached to the unit, and trucking details are arranged.

This whole process normally takes 5 to 7 working days, depending on the size of the airend and the degree of damage. We have set up our shop so the work flows through on an orderly path to insure that all our inspection steps and quality controls are adhered to. All rebuilds are backed by our standard 400 Day warranty. Ask us how you can extend this warranty to two years at no additional cost. See our airend warranty sheet for complete details.